Computer-Aided Repair Design (CARD) is a game-changer in the automotive industry, revolutionizing auto body repairs and restorations with advanced software tools. By creating precise 3D models of damaged parts, CARD enhances assessment, planning, and creativity for complex collision scenarios. This digital approach streamlines workflows, reduces human error, minimizes waste, and boosts customer satisfaction. From simple glass repair to intricate metalwork, CARD's versatility offers unparalleled precision, accuracy, and efficiency compared to traditional methods, transforming industrial repairs and elevating the quality of services provided by auto body shops.

Computer-Aided Repair Design (CARD) is transforming industries by streamlining complex maintenance tasks and enhancing efficiency. This powerful tool offers a promise of improved precision, reduced downtime, and cost savings, but it’s shrouded in myths that hinder its adoption. This article debunks common misconceptions surrounding CARD, highlighting its versatility, affordability, and ease of implementation. It explores real-world applications in manufacturing, automotive, and aviation industries, demonstrating its potential to revolutionize repair processes.

- The Promise and Power of Computer-Aided Repair Design

- – What is computer-aided repair design (CARD)?

- – Advantages of using CARD techniques in industrial settings.

The Promise and Power of Computer-Aided Repair Design

Computer-aided repair design (CARD) promises a new era in auto body repair, auto frame repair, and vehicle paint repair processes. By leveraging advanced software tools, technicians can achieve unprecedented precision, efficiency, and accuracy. This innovative approach streamlines complex tasks, from measuring and modeling damaged components to generating detailed repair plans and cost estimates. The power of CARD lies not only in its ability to reduce human error but also in its potential to enhance creativity and problem-solving capabilities.

With computer-aided design, the auto industry can embrace a more data-driven approach, minimizing reliance on traditional guesswork. This technology enables technicians to access vast libraries of digital models, ensuring they have all the necessary information at their fingertips. Moreover, CARD facilitates better communication among stakeholders, as digital plans and specifications can be easily shared and modified in real time. Ultimately, this cutting-edge technique promises to revolutionize repair processes, delivering superior results while optimizing workshop workflows and customer satisfaction.

– What is computer-aided repair design (CARD)?

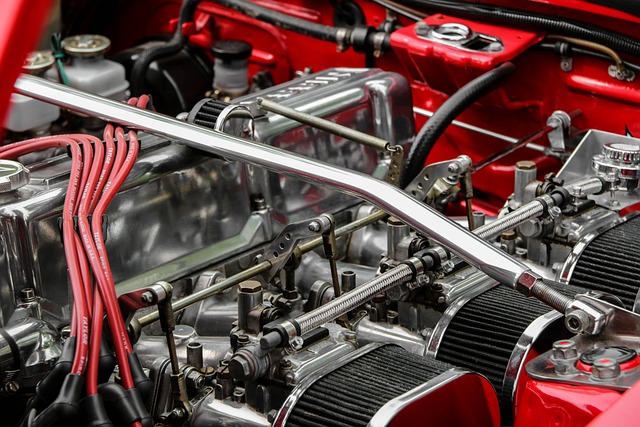

Computer-aided repair design (CARD) is a revolutionary technique transforming the landscape of automotive repairs and car restoration. This innovative process leverages advanced software to streamline the design and planning stages of vehicle bodywork, specifically for collision repair services. By digitizing the traditional drawing board methods, CARD offers precision, speed, and enhanced visual aids compared to manual drafting.

It enables repair technicians to create detailed 3D models of damaged vehicle parts, allowing them to accurately assess and plan repairs. This technology is especially beneficial in complex collision scenarios, ensuring that every angle and dimension is considered before any work begins. With CARD, collision repair services can achieve more efficient workflows, reduce errors, and ultimately deliver higher-quality vehicle bodywork restoration outcomes.

– Advantages of using CARD techniques in industrial settings.

Computer-Aided Repair Design (CARD) techniques offer numerous advantages in industrial settings, revolutionizing how repairs and restorations are carried out. Unlike traditional manual methods, CARD systems provide precision and accuracy, enabling auto body shops and vehicle restoration specialists to perform complex tasks with efficiency. By utilizing specialized software, these techniques allow for detailed planning and visualization of repairs, from simple auto glass repair to intricate metalwork, ensuring every step is executed flawlessly.

The benefits extend further, offering cost-effectiveness by minimizing material waste and reducing the time typically required for manual labor. This technology also facilitates easy modifications and adjustments during the repair process, promoting flexibility in meeting unique or unconventional requirements. With CARD, auto glass repair, and vehicle restoration processes become streamlined, making them more accessible and reliable for industrial professionals, ultimately enhancing the overall quality of services provided by auto body shops.

Computer-aided repair design (CARD) offers a promising and powerful approach to industrial maintenance, revolutionizing traditional methods. By leveraging advanced digital tools, CARD techniques enhance efficiency, reduce costs, and improve overall equipment effectiveness. Debunking myths and embracing the facts about CARD can foster its adoption, leading to more robust and sustainable industrial practices.